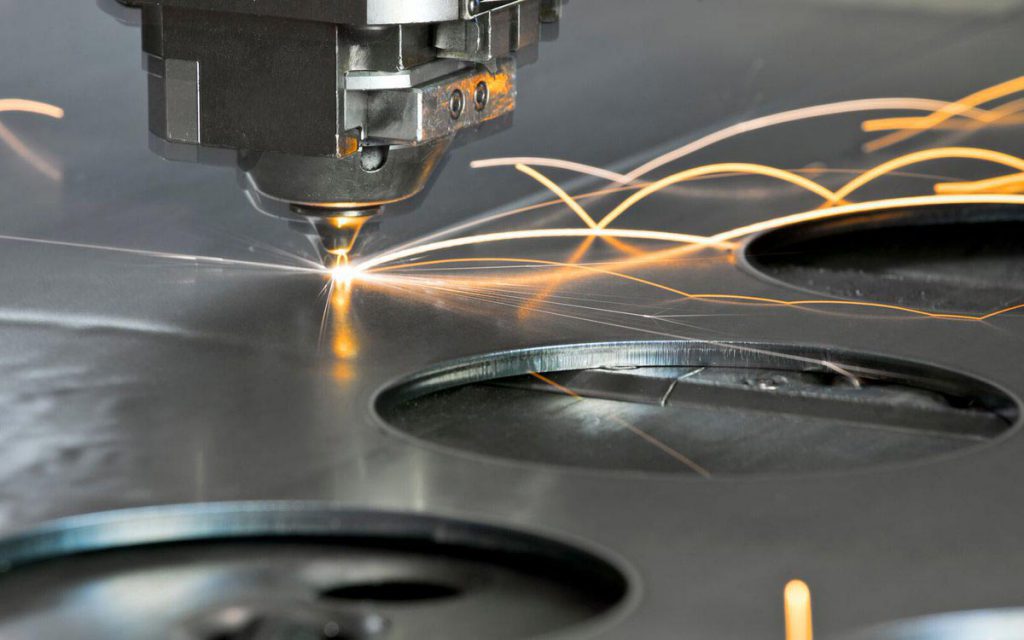

2D Sheet Metal Laser Cutting

Speed and precision, even on special steels

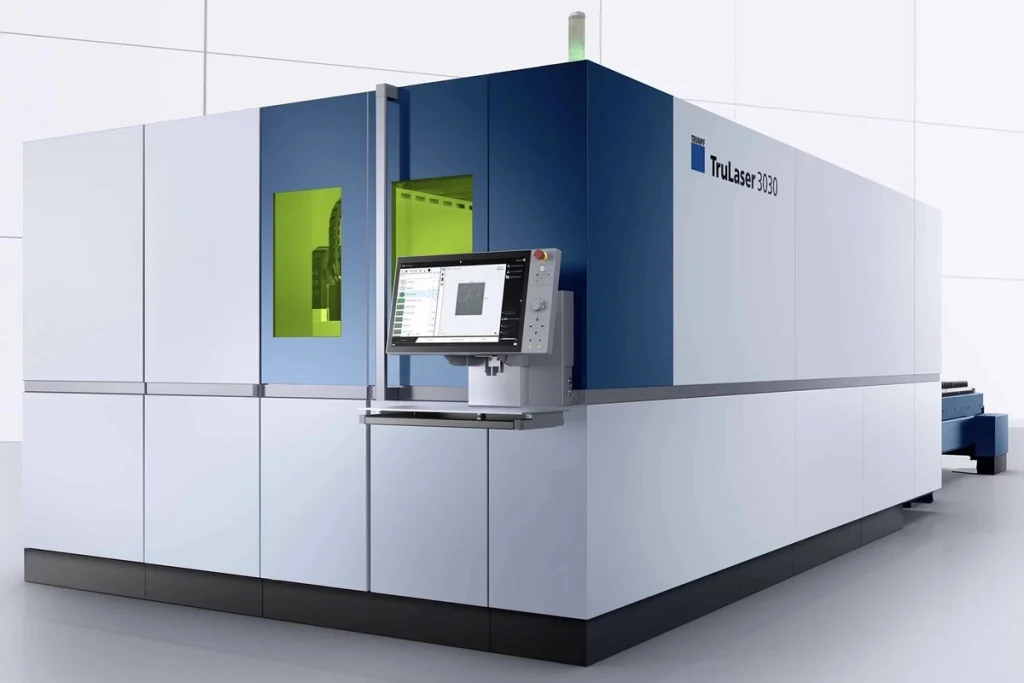

Cremonini‘s extensive experience in laser cutting technology allows us to produce complex works of various sizes, even in small batches, to meet our customers’ needs. Our Trumpf Trulaser 3030 fiber 6000 system is equipped with an automatic loading/unloading and storage system. We work with a wide range of metal sheets made from different materials, formats, and thicknesses, ensuring quick delivery times and adherence to agreed deadlines.

The Ready 4.0 connection enables remote and real-time control of production processes, facilitating intelligent production management and providing greater flexibility in response to market demands.